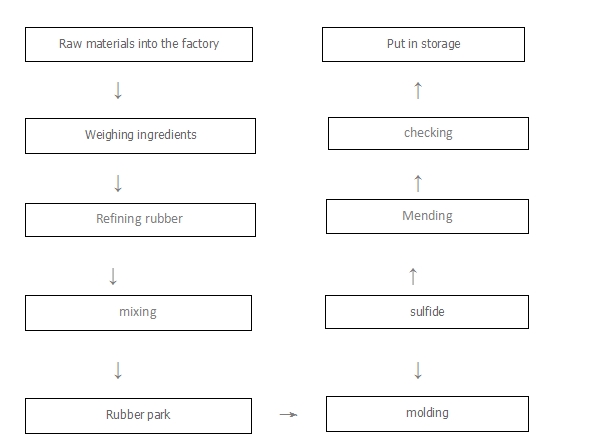

·The production process

·The ingredients

1. crushing raw materials, auxiliary materials of large material smash into each do with no more than 50 g;

2. raw rubber drying: drying glue temperature 50 ~ 60 ℃, drying glue time 24 h and 36 h;

3. dressed before production labor insurance supplies (overalls, gloves, etc.) to prepare for work ahead of schedule;

4. weighing equipment before use must carry on the correction;

5. according to the requirements of dispatching list of match Fang Chan accurately weighing;

·Rubber mixing

1. rubber mixing process from washing rubber, rubber cutting stripping before rubber skin or with the brush to clean the surface sand and impurities, lest affect quality of rubber;

2.Plasticate will roll away from 2 to about 1 mm, open cooling water cools the roller, the mixing time in roll gap, for there is no accumulation of roller, and then within the chassis glue back into turn 90 degrees, repeated more than 8 ~ 12 times;

3. raw rubber to timely after the lower cooling, isolation layer stacking;

4. all kinds of chelating agent, modifier are added into the raw rubber, in rubber mixing machine mixing, mixing rubber.

·Press craft

1. prepare mixed good glue into flake, 30 ~ 60 mm cut into thin strips, and according to the specifications of the sealing ring, cut into several segments and set aside.

2. according to the product weight said strip, with forceps into each circle, in the mold.

3. will die and mold, put in moulding machine, mould press + / - 1℃, temperature control precision mold edge of plate edge should not be less than 50 mm, pressing time, after stripping out, and promptly trim flash, deburring.

4. pressing process parameters, the temperature is 142 ℃ ~ 152℃, pressure of 10 ~ 20 mpa. The time is 3 ~ 8 seconds.