·The pipeline

1.slot construction craft, according to the construction site environment, the groove depth, the underground water level, soil condition, construction equipment and seasonal influence factors such as comprehensive selection.

2.groove bottom width of dispute, in accordance with the groove depth, ground water, soil conditions and easy to operate, these provisions empty groove width table can be used for reference in the involved, the construction unit.

3.underground water level is higher than the chamfered bottom elevation, when construction must take effective measures to underground water level dropped to the bottom of the channel under 0.3 to 0.5 meters.

4.excavation groove, should strictly control the base elevation, shall not be disturbed base and overexcavation.Basement involved in elevation above 0.2 to 0.3 meters of undisturbed soil shall be preserved, before laying with artificial stripping to the design elevation.

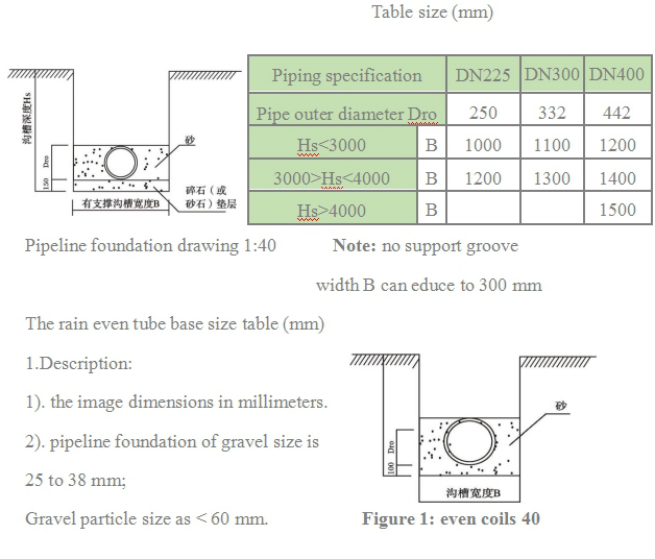

Piping specification | DN225 | DN300 | DN400 | DN500 | DN600 | DN800 | DN1000 |

Pipe outerdiamete Dro | 250 | 332 | 442 | 553 | 665 | 874 | |

Groove width | 650 | 750 | 950 | 1053 | 1165 | 1478 | |

· Buried depth and foundation

1.pipe under the roadway roof minimum thickness of overlying soil is 0.7 meters.

2.pipe base and choose the material should comply with the design requirements.These provisions, the basis and buried depth of page 4 approach can be used for reference in the design and relevant units (without groundwater and basement for hard formation, figures in the table can be reduced.)

3.when pipe roof minimum covering and maximum covering cannot meet, should be used separately designed by the design unit or structure strengthening measures.

4.when crossing the railway, road embankment, retaining wall and the obstacles such as building material, reinforced concrete, steel pipes, cast iron and other materials should be set up to make the protection of the casing, casing diameter should be greater than FRPP composite outer diameter 300 mm, casing should be according to the regulations of design units and departments.

· The piping installation

1.before laying the pipe section should be by the quality inspection, does not accord with a standard shall not be used.Pipe handling generally available manual handling at the scene, but have to put it gently lift, it is forbidden to drag on the ground directly.

2.tube can generally be carried out by artificial, under the pipe to the bottom of the channel construction personnel by the ground personnel. Chute nonmetal rope are available, and also make pipe smoothly put inside groove, it is forbidden to use metal rope hook for pipe or tubing roll into the slot at the edge of the groove.

3.pipe socket should be well flow direction, flow direction, under socket from downstream to upstream, in turn, installation.

4.interface, should be first on the lining of the mouth and clean up the outer wall socket, coated with lubricant, then use the hoist with pry at the same time, to be installed along the axis of the alignment of pipes slowly inserted in the socket, one day, in turn, installation.Pipe insert must be in place.DN225 insert 135 + 5 mm, inserted 12 to 165 + 5 mm, DN400 inserted to 205 + 5 mm.

5.rubber sha-lu position should be placed in the second rib tube socket between the groove.

6.pipe length adjustment, usable hand saw cutting, but the vertical section should level off, should not be damaged.

7.rainy season construction, should take measures to prevent pipe floating.

8.pipe connected to the inspection shaft, be determined by design, practice on page 6 of this standard can be used for reference in the involved and the relevant units to use.

· The backfill

1.pipe installation acceptance rear can implement backfill, pipe trench backfilling from basics to the tube within the scope of more than 0.7 meters.Must use artificial backfill, it is strictly forbidden to back fill earth with mechanical bulldozing, tube top 0.7 meters, machinery from the pipe can be used on both sides of the backfill and compact and rolling at the same time.

2.groove backfill should begin from the pipeline and inspection Chad well on both sides of the symmetrical backfill at the same time, each layer of backfill height less than 0.2 meters, backfill material and compactness requirements should comply with the regulations of design.

3.from the end of tube to tube top above 0.4 meters within the scope of the backfill material, should not contain silt, organic matter, stones, bricks and other objects.